[Publication]

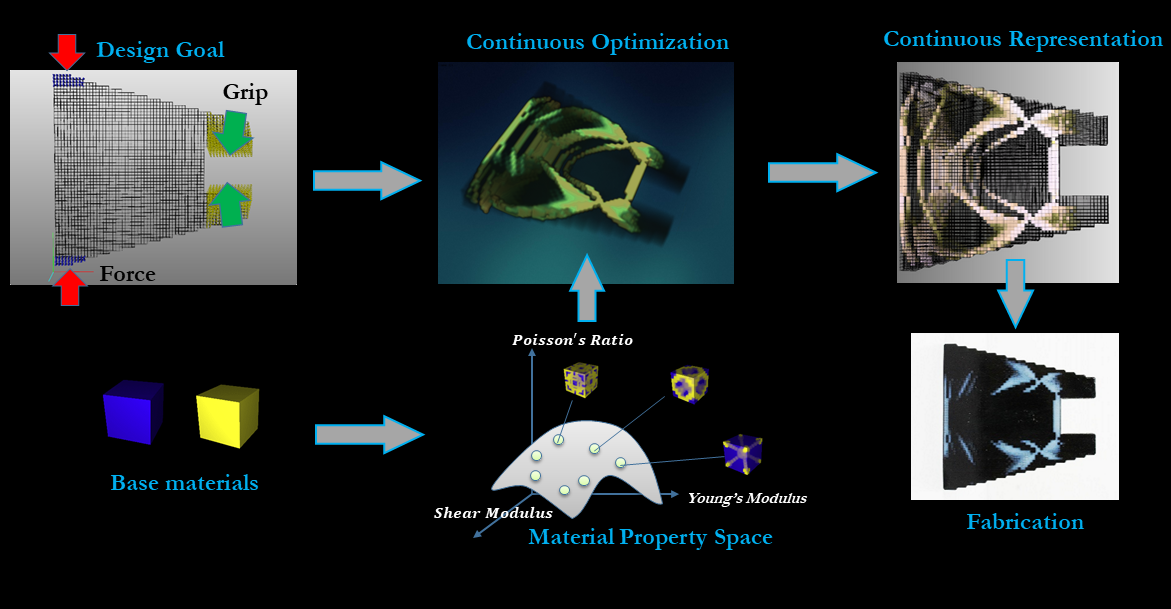

In this paper we present a novel two-scale framework to optimize the structure and the material distribution of an object given its functional specifications. Our approach utilizes multi-material microstructures as low-level building blocks of the object. We start by precomputing the material property gamut – the set of bulk material properties that can be achieved with all material microstructures of a given size. We represent the boundary of this material property gamut using a level set field. Next, we propose an efficient and general topology optimization algorithm that simultaneously computes an optimal object topology and spatially-varying material properties constrained by the precomputed gamut. Finally, we map the optimal spatially-varying material properties onto the microstructures with the corresponding properties in order to generate a high-resolution printable structure. We demonstrate the efficacy of our framework by designing, optimizing, and fabricating objects in different material property spaces on the level of a trillion voxels, i.e several orders of magnitude higher than what can be achieved with current systems.

Bo Zhu, Melina Skouras, Desai Chen, Wojciech Matusik. Two-scale Topology Optimization using Microstructures. 2017. ACM Transaction of Graphics, 36(5). [pdf]

[Presentation]

[Examples] (click image for video)

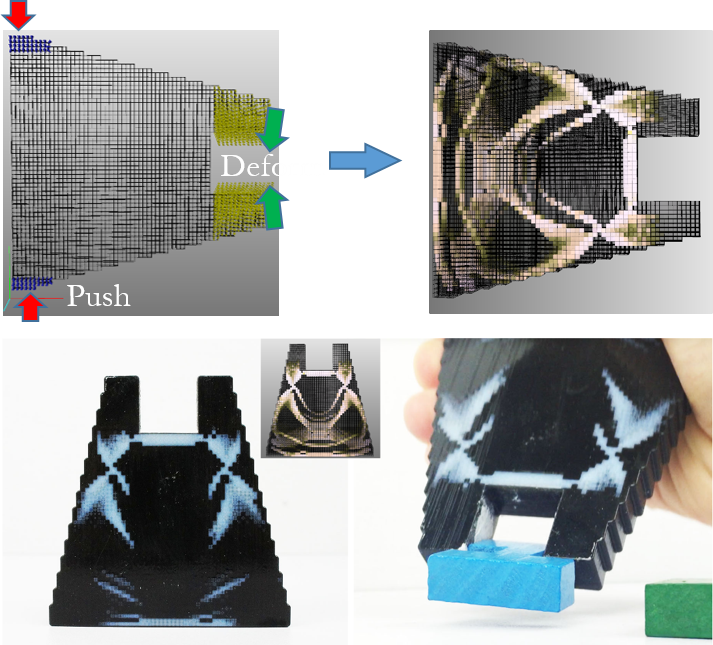

Soft robotic gripper. we design a functional gripper using our algorithm with microstructures that can grasp objects by moving their tips when external forces are applied to their extremities.

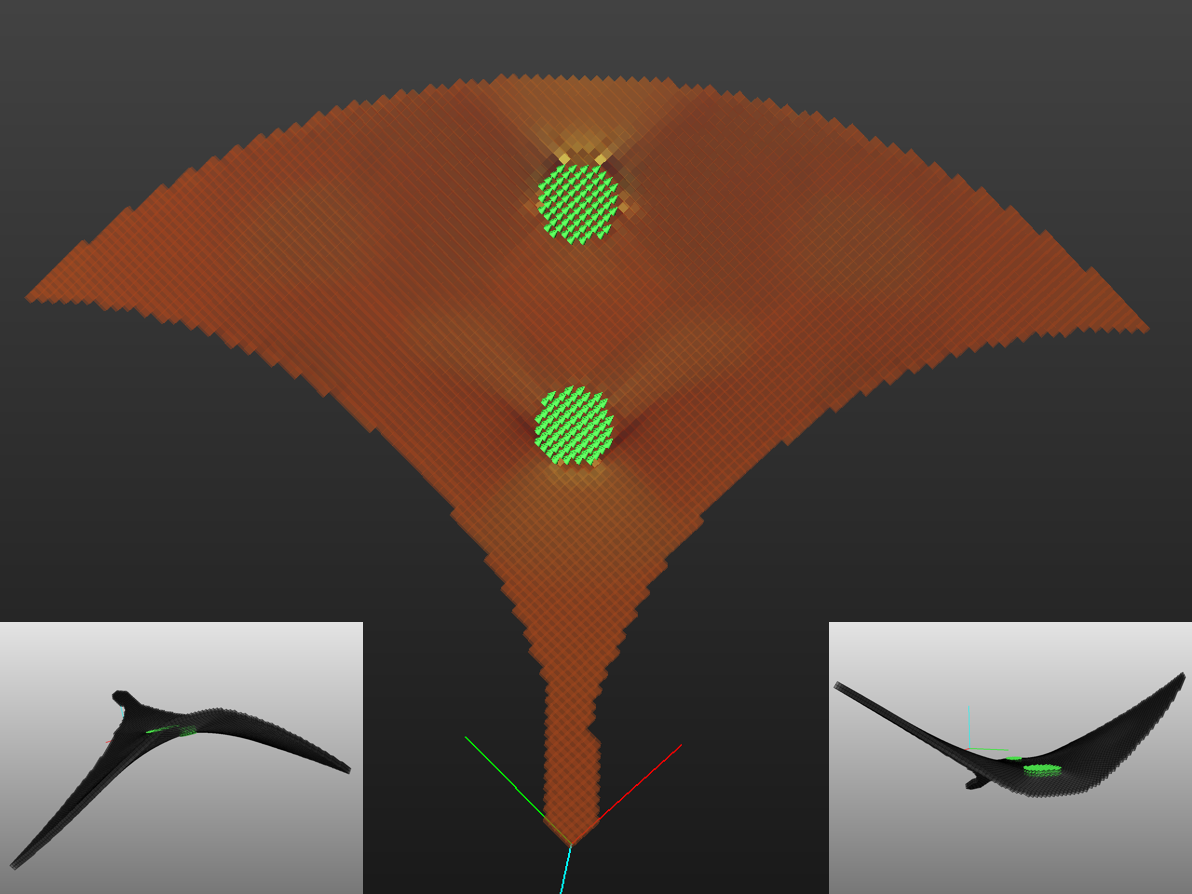

Soft swimming ray. We design a soft way with swimming motion modes. The soft mechanisms for flapping wings are embedded in the material by topology optimization. The wings of the ray are specified to flap up and down when vertices on its spine contract and expand.

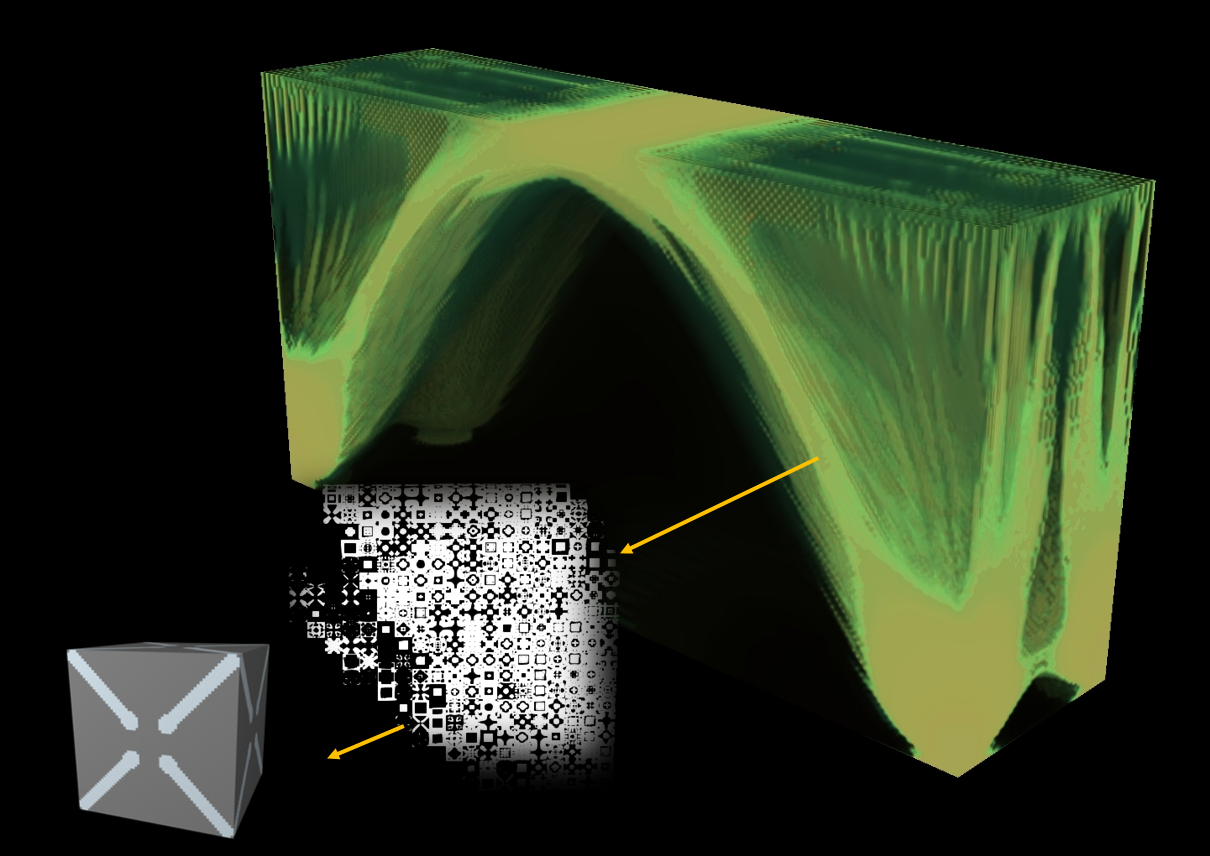

Bridge. We demonstrate the capability of our algorithm on solving high-resolution topology optimization problems. The bridge optimization problem is within a 34 by 17 by 8 inch volume, corresponding to a trillion of printing voxels.

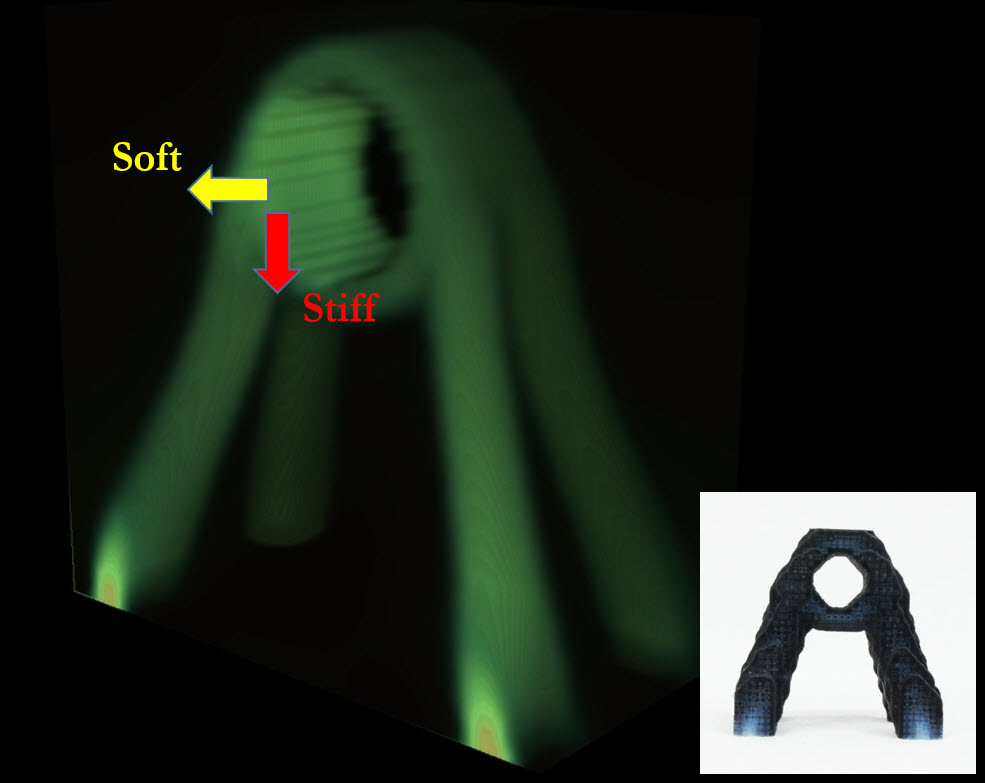

Flexure. We design a mirror flexure using our algorithm with two different objectives for stiffnesses. The Y direction is set to be very stiff and the Z direction to be very soft.

[Youtube]