Digital Composites

Media Coverage:

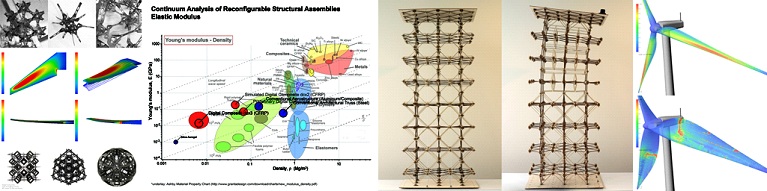

MIT News

Digital Composites is a structural construction system that enables large scale shape morphing mechanics to be implemented entirely flexurally, with high strength, light weight, and three dimensionally tunable stiffness characteristics. This is accomplished with a volumetric kit-of-parts strategy, which effectively distributes loads and requires few different part types to achieve exponentially varied structures. Furthermore, simulation and design methods improve considerably upon conventional high performance and flexural structure design, whereby a small change in one part can require incremental re-design and re-evaluation of all other parts. Tunable compliance allows for simple actuators (i.e. internal winch cables) and effective distribution of the forces typically produced in traditional actuation schemes.

Aerostructures such as wind turbine blades require constant adjustment to account for differences in wind (i.e. that depend on dimensions such as altitude and proximity a support structure). This adjustment is commonly implemented with actuation systems (by turning the entire blade by its root, or less commonly with ailerons) that rely on rigid components attached with costly bearings that need to handle enormous loads.

Another problem with terrestrial wind turbines is that they are currently designed around the largest dimensions that can be transported on roadways. A method of assembling (and repairing or reconfiguring) aerostructures on-site would allow for better optimized systems. Commercial aircraft structures face similar problems, with substructure manufacturing often performed in different countries to the final assembly plant.

Current work is focused on large scale aerostructures and energy harvesting, but Digital Composites are well suited to any application with distributed loading characteristics (i.e. bridges, buildings). The fundamental benefits scale down to 10µm scale, and we are pursuing the possibility of employing molecular machinery for fabrication of high performing biomaterials. This invention has been recently submitted for US and international patents, and ongoing work is in collaboration with industry partners (Spirit Aerosystems and Moog Inc.).

Cheung, K. C., and Gershenfeld, N. Reversibly Assembled Cellular Composite Materials Science (in press, published online 15 August 2013). doi:10.1126/science.1240889