Deployable Safety Helmet

When a helmet isn't being worn, it takes up a lot of excess space. Before they even reach users, they must be packaged as fragile items in robust containers. A lot of the volume of a bicycle helmet is air (in the foam), and the packaging is an effort to make sure that this air stays in. Why not leave the insertion of air until the helmet needs to be worn?

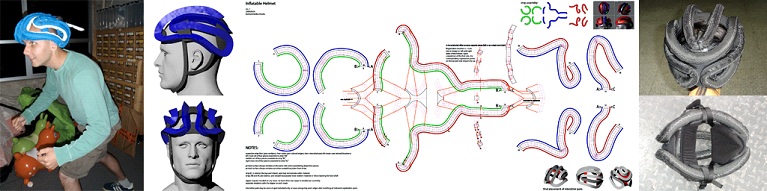

The deployable helmet is a ballistic nylon tube, shaped into a helmet, with a standard (700c) bicycle inner tube as a bladder that can be filled with either rigid thermoset foam or air. Thermoset foam can be supplied in a two part dispenser, like tube sealant dispensers, with chemistry similar to expand-to-fit packaging systems. When using air, the user simply needs to let the air out of the tube, in order to pack the helmet into the size of a wallet. A high strength zipper runs the length of the outer nylon tube, to allow replacement of the inner tube/bladder.

The mechanics of this design as a crash protection device are similar to conventional helmets when filled with foam, and even better when filled with air (due to the progressive stiffness afforded by the volume of compressible gas). Potential target users include bike-sharing systems, as they can be efficiently packaged and dispensed at bike-share kiosks.

The Deployable Safety Helmet was designed, prototyped, and tested with support from CBA and Makani Power Inc., in collaboration with Saul Griffith