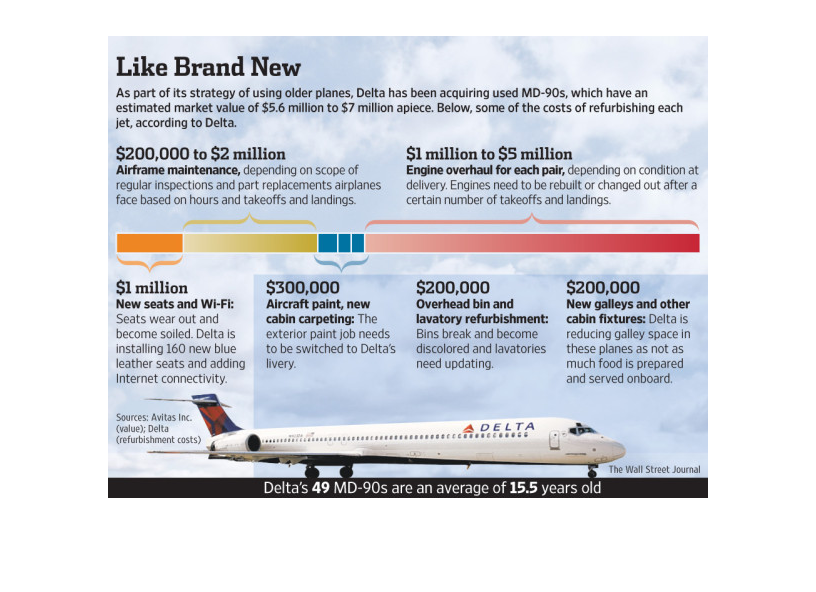

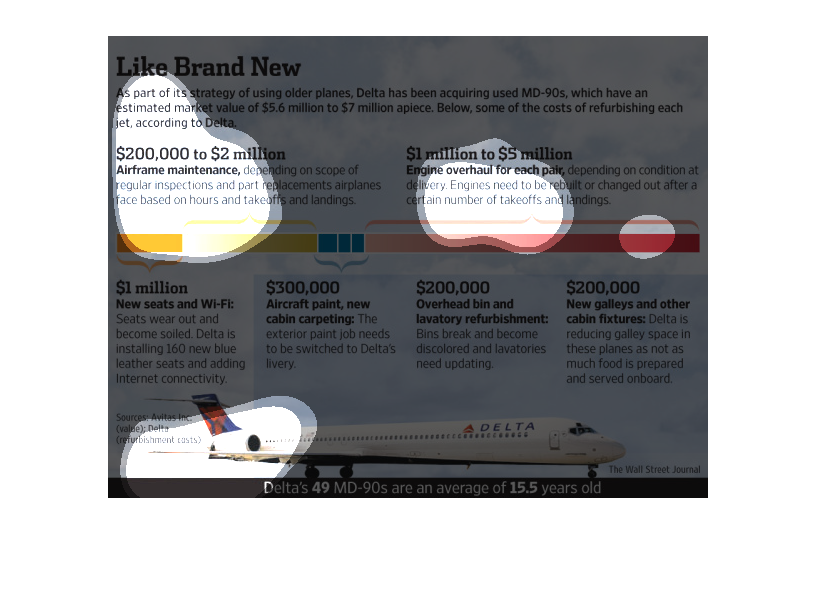

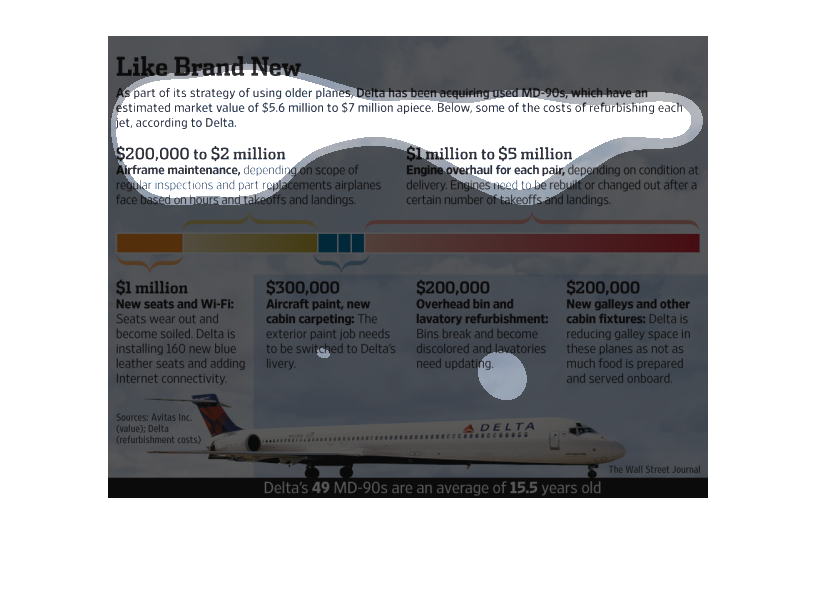

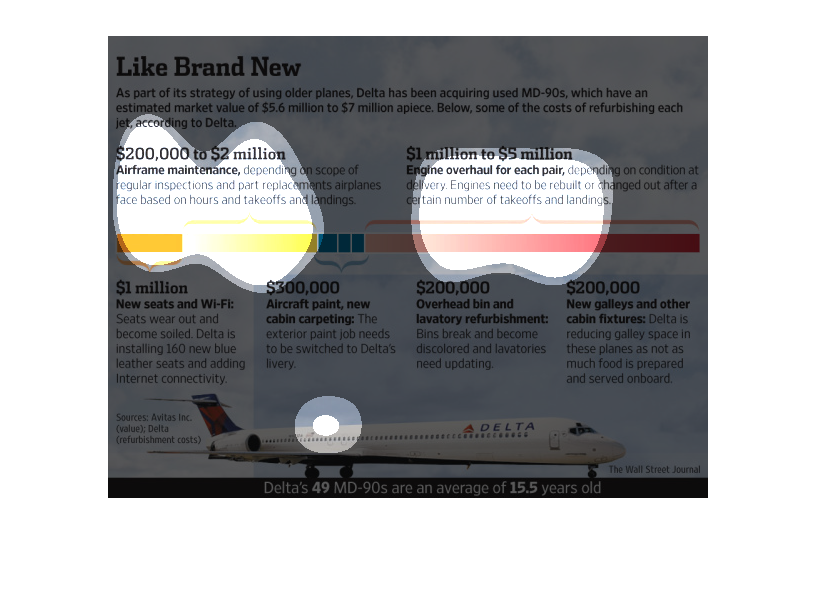

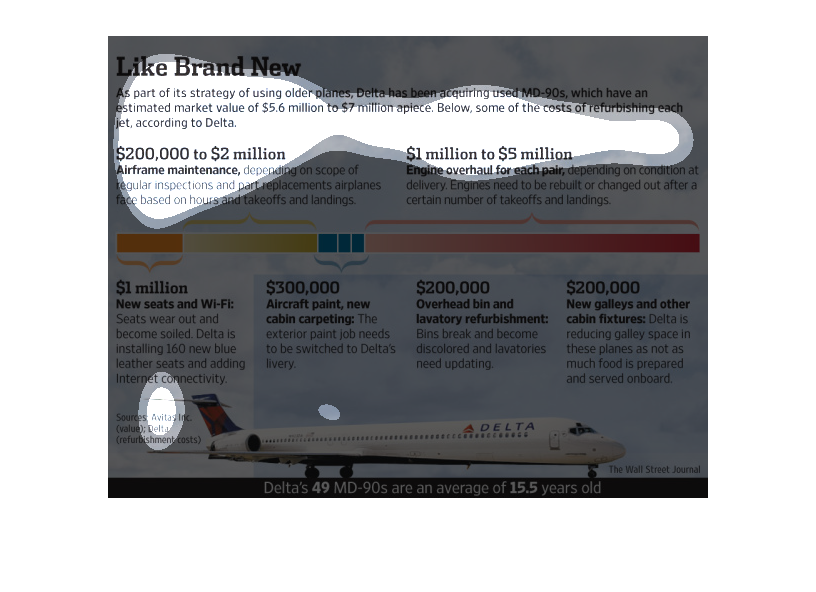

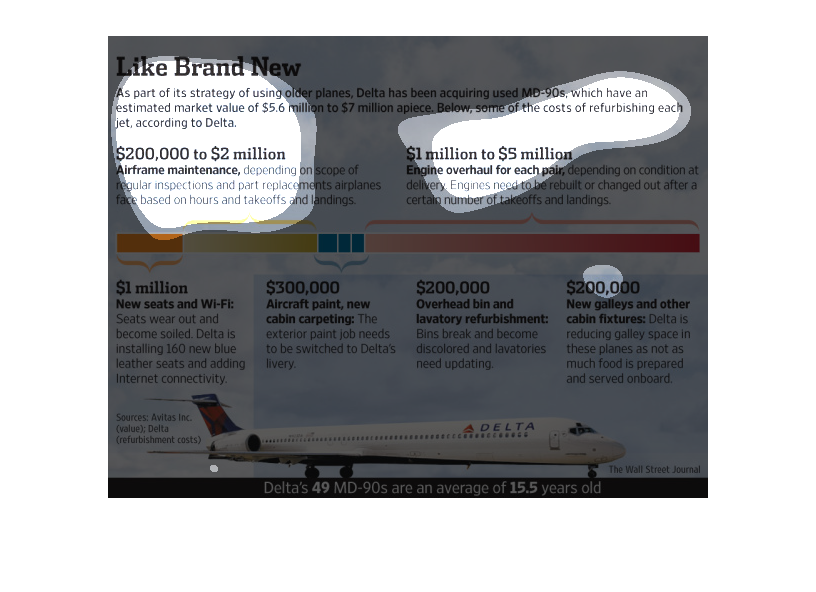

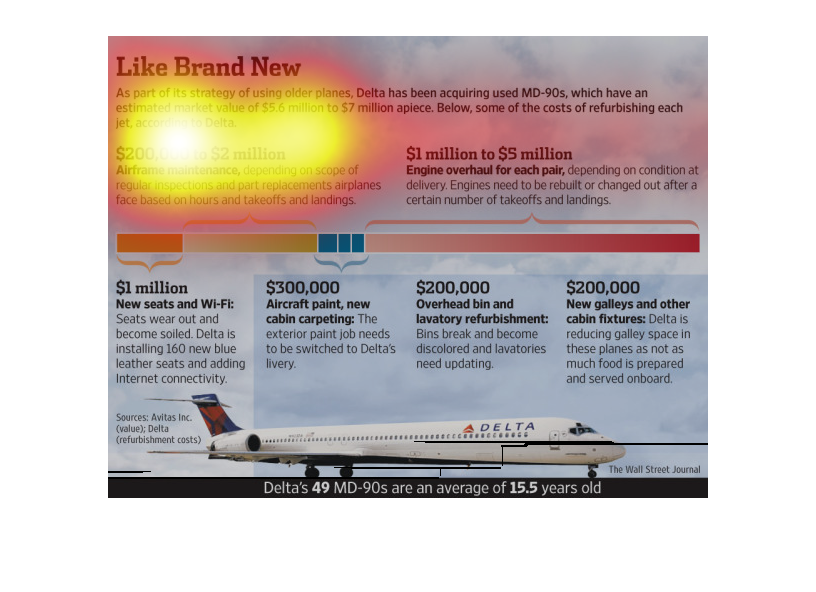

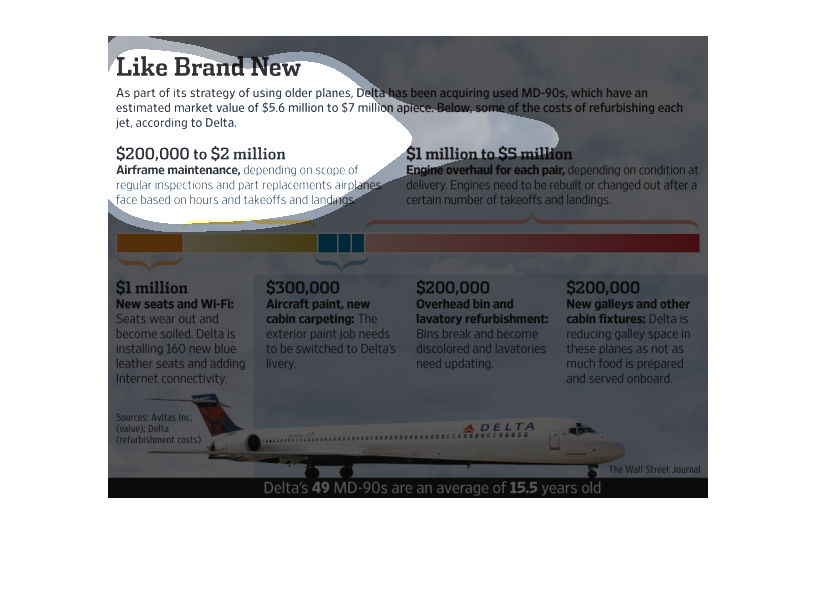

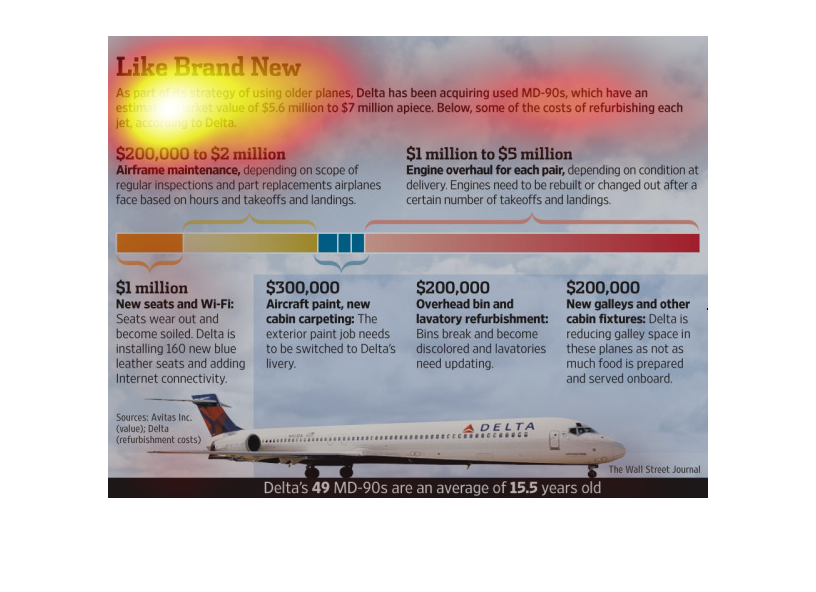

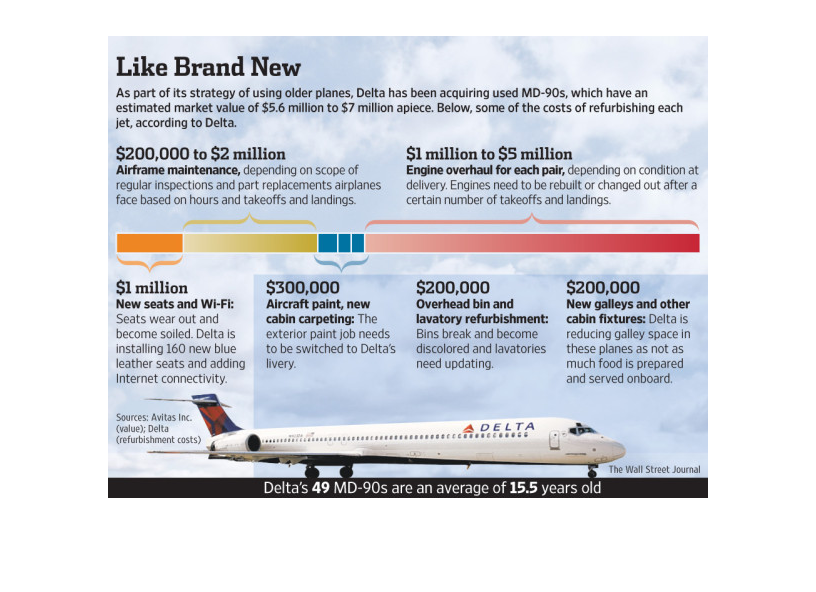

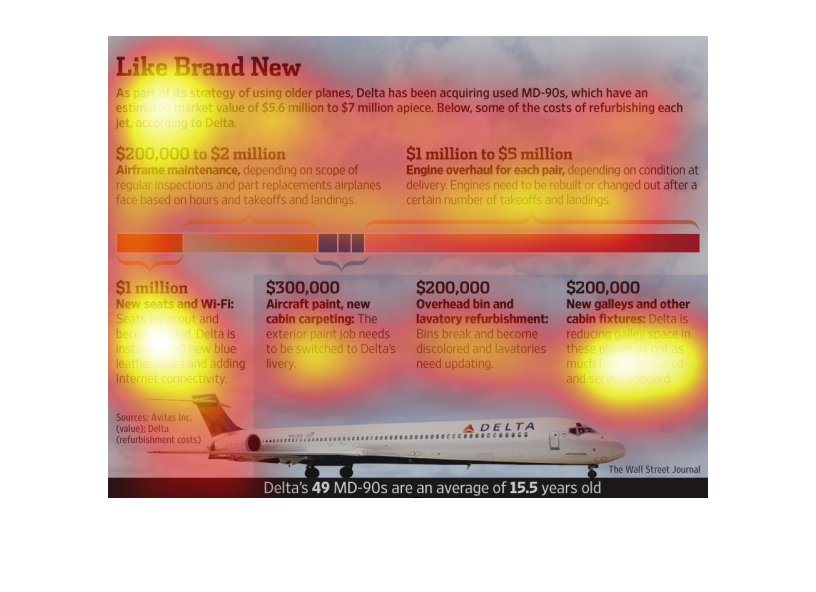

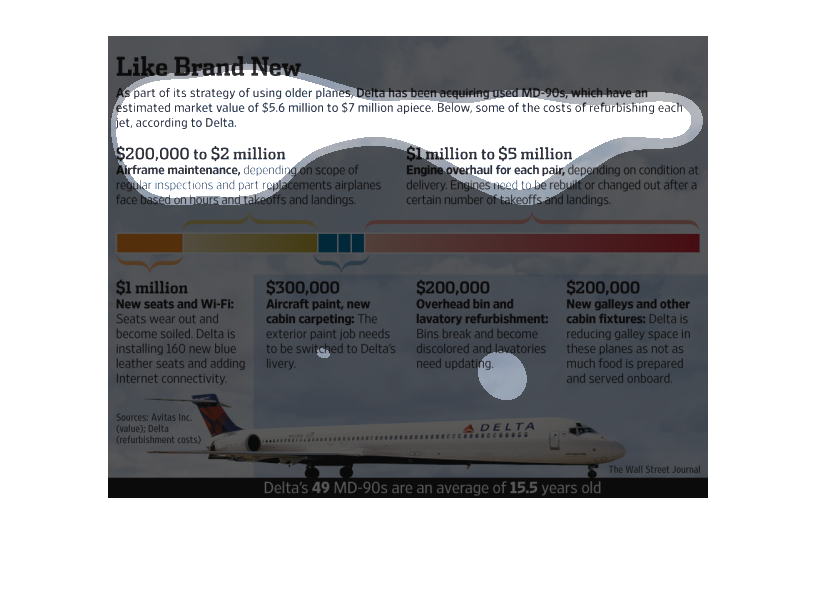

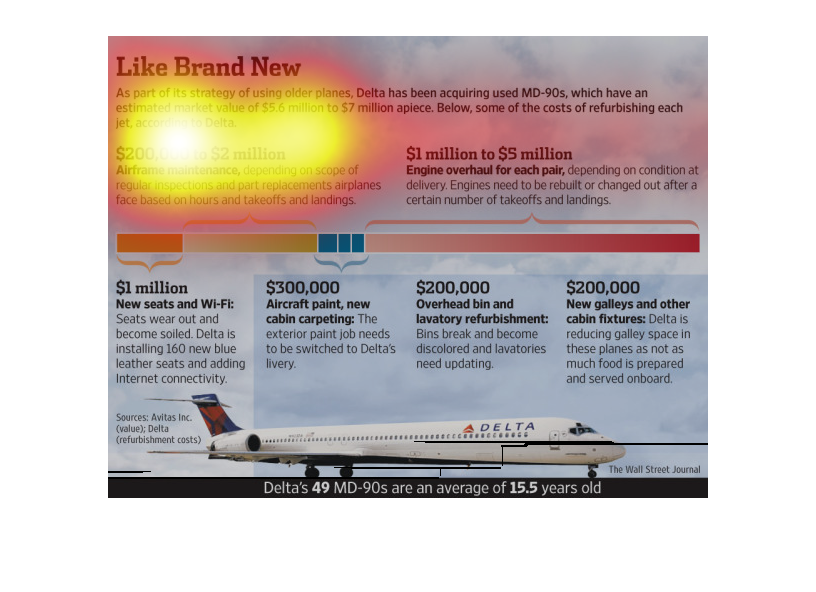

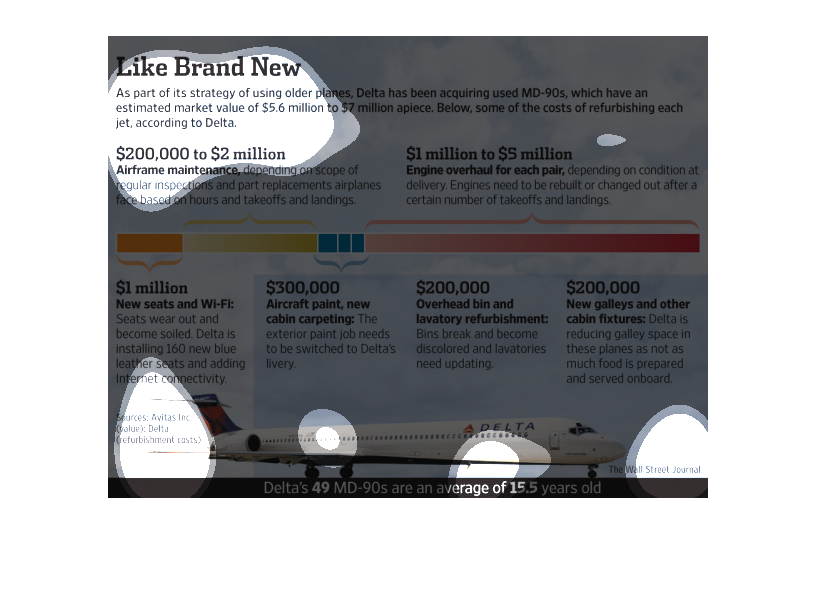

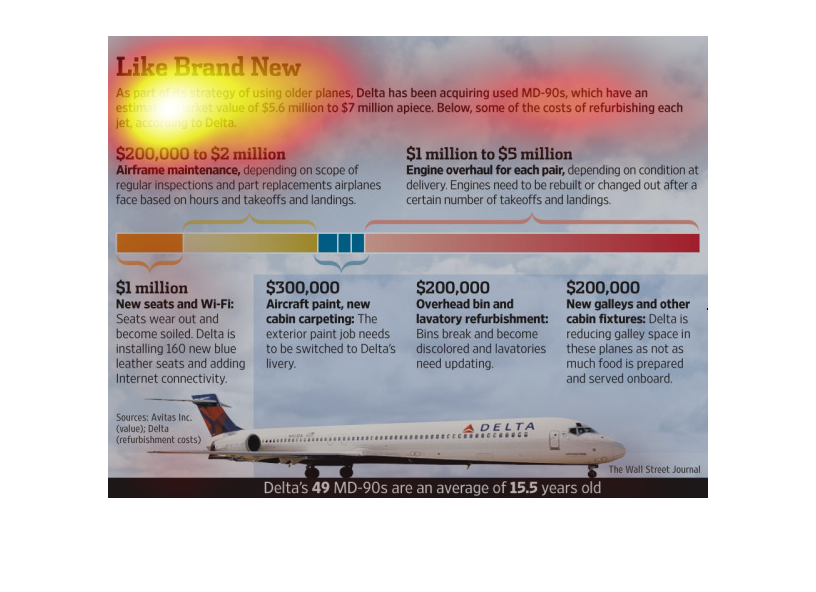

This graph shows the correlative costs between Delta buying a plane that needs refurbished

and the amount of money each project should cost. Wifi/seating, paint and carpeting, overhead

bin and lavatory remodel, and new galleys are the refurbishing options covered by this graph.

This graph breaks down the costs for Delta of repairing used MD-90's that they buy, to bring

them up to standard. They spend the most on engine overhaul and airframe maintenance.

The image depicts Delta's strategy of acquiring used planes, which at times have a lower cost

than the cost of refurbishing planes, in an effort to save money and better complete in the

marketplace.

Delta airlines has been buying older planes and refurbishing them. The value of the planes

are $5.7 million. In order to make each plane serviceable, Delta will need to spend approximatley

$1 on new seating, between $200,000 and $1 million on air frame maintenance, $300,000 on carpent

and paint, $200,00 on new overhead bins, $200,000 on new galleys, and the largest expense,

between $1 to $5 million overhauling the engines.

A chart breaking down how much Delta Airlines spends on refurbishing old planes, showing how

much money each piece of the plane costs in the long run.

The caption for this chart or poster is, "Like Brand New". The information contained here

in describes Delta Airlines plan to refurbish used planes and make them suitable for their

commercial fleet. At the bottom of the graphic is an image of a Delta air craft. Hoovering

about halfway up the page, above the aircraft are informational blurbs regarding the changes

that would take place to these aircraft, and the associated costs per upgrade.

This chart describes like brand new. Specifically, as part of its strategy of using older

planes, Delta has been acquiring used MD-90's, which have an estimated market value of $5.6

million.

This chart shows how Delta has been purchasing older planes and refurbishing them with new

seats and Wifi, aircraft paint, overhead bins and new lavatories, and new galleys and cabin

furniture as well as the associated costs.

Chart details Delta's plan to buy old airplanes and refurbish them for future use. Engine

repair refurbishment is the highest cost with a range of 1-5 million dollars

This is a series of statistics and a graph depicting the strategy that Delta Airlines is employing

to refurbish and use older planes such as the MD-90.

The headline for this image speaks of an effort to transform the condition older planes in

the pursuit to make the as new. The report within this image tells us how Delta acquired a

number of used MD-90s for their special project. The information states that each of these

jets had an estimated market value of $5.6 million to $7 million a piece.

As a part of its strategy Delta airline has been acquiring uses MD-90s an older airplane and

has been refurbishing them. The costs of each was 5.6 to 7 Million dollars. The chart shows

some of the costs associated with refurbishing each.

As a cost saving measure, Delta Airlines has decided to rebuild older airplanes instead of

purchasing new ones. This graph shows the costs associated with that plan.

DELTA HAS BEEN ACQUIRING USED MD-90S WHICH HAVE AN ESTIMATED VALUE. THE INFOGRAPHIC BELOW

SHOWS SOME OF THE COST OF REFURBISHING EACH JET ACCORDING TO DELTA.